Do Diamond blades have real diamonds?

Despite their name, diamond blades are not entirely made of diamonds but are instead constructed using a sophisticated combination of materials that deliver exceptional cutting performance. At the heart of each blade is a core of high-quality steel, over which a layer of powdered metal is meticulously applied. This metal layer is embedded with diamond crystals, the key component that gives the blade its cutting edge. However, these aren't the type of diamonds found in jewelry; they are synthetic diamonds, produced through a high-temperature, high-pressure synthesis process. This manufacturing method ensures that the diamonds are exceptionally hard and durable, making them ideal for industrial applications.

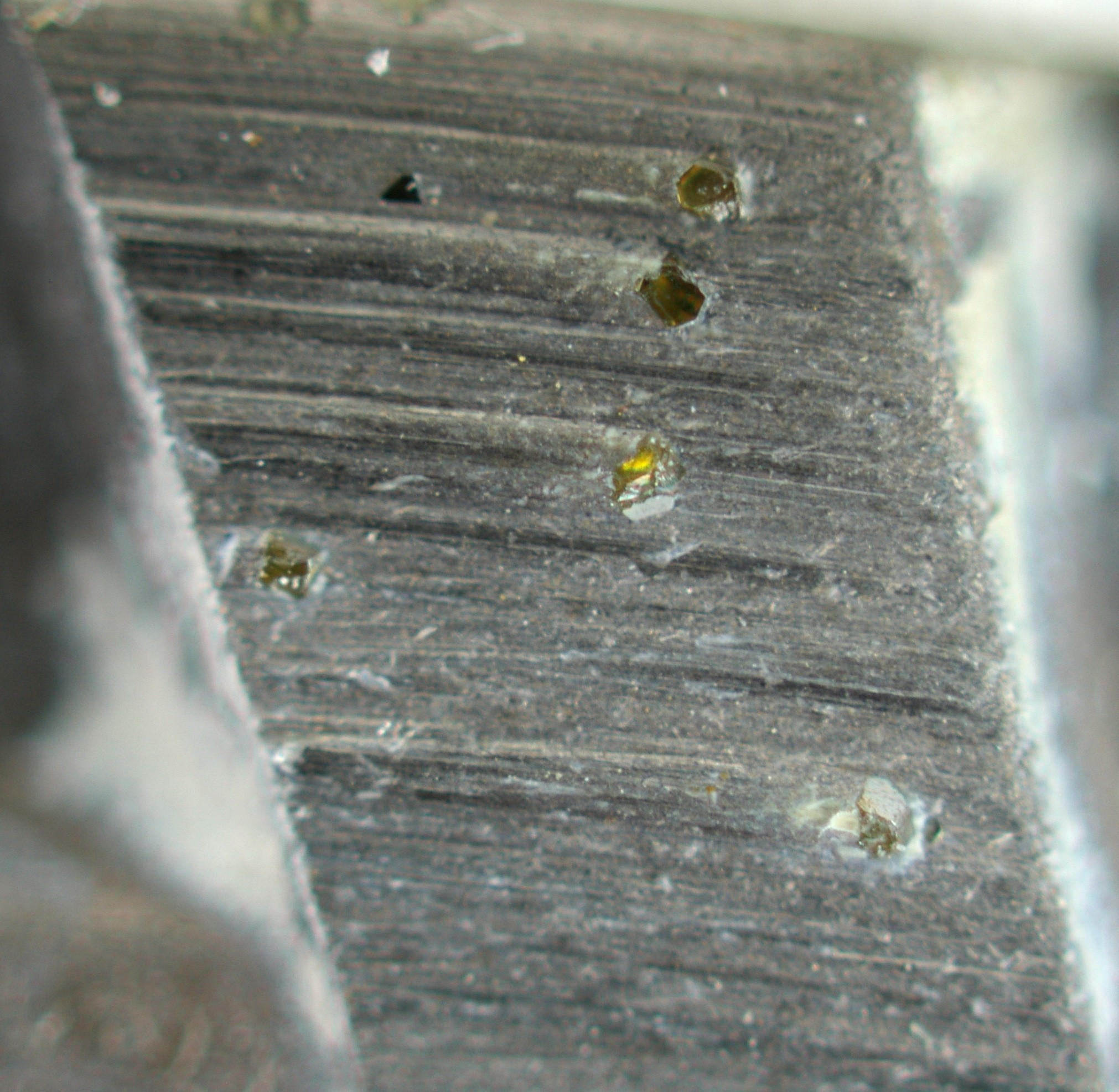

The concentration and quality of the diamond crystals within each segment of the blade are critical factors that directly influence the tool's performance. A higher concentration of diamonds typically results in a more aggressive cutting action, allowing the blade to slice through tough materials with ease. The quality of the diamonds also plays a significant role, as higher-grade diamonds are more resilient to wear and tear, extending the blade's lifespan and maintaining its cutting efficiency over time.

The diamond-tipped cutting edge is designed for maximum efficiency, ensuring that each cut is precise and clean, even when working with the most challenging materials. This efficiency is not just about speed; it's about ensuring that every job is completed to the highest standard, making each blade an investment in the quality and professionalism of your work.

However, it's crucial to match the blade to the material you're cutting. Using the wrong blade for a particular material can quickly dull the cutting edge, reducing its effectiveness and potentially leading to costly delays. For instance, a blade designed for cutting soft materials may not perform well on harder substances, leading to premature wear and a loss of cutting power. Therefore, understanding the specific requirements of your job and selecting the appropriate blade is essential to maximizing the performance and lifespan of your diamond blade.

In summary, while diamond blades are engineered to deliver top-tier cutting performance, their effectiveness is heavily dependent on the quality and concentration of the synthetic diamonds embedded within them. These blades represent more than just a tool—they are a strategic investment in the quality and efficiency of your work. But, to truly harness their potential, it's crucial to pair them with the right material, ensuring that each cut is as sharp and efficient as possible.