Step 1

Requirement Collection

Please submit your detailed requirements, including the type of stone, application scenario, desired abrasive type, and specifications.

Please submit your detailed requirements, including the type of stone, application scenario, desired abrasive type, and specifications.

Our technical team will engage with you in one-on-one detailed communication to provide professional advice and solutions.

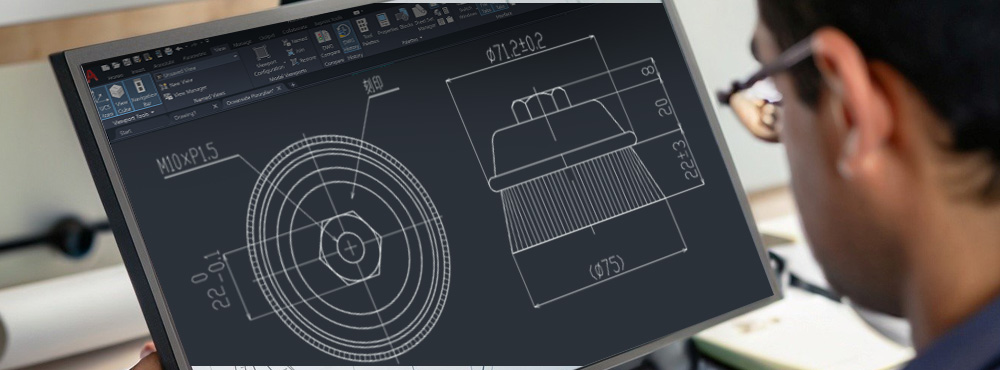

We will design initial samples based on your requirements and provide them for your confirmation and trial.

Based on your feedback, we will design the final custom plan and confirm the specific shape, size, material, and process of the abrasive brush.

We will manufacture the abrasive brush according to the confirmed plan, strictly controlling production quality and process.

After production, we will deliver the abrasive brush to you and provide necessary installation guidance and support.

We offer comprehensive after-sales service, including product usage guidance, maintenance advice, and problem resolution.

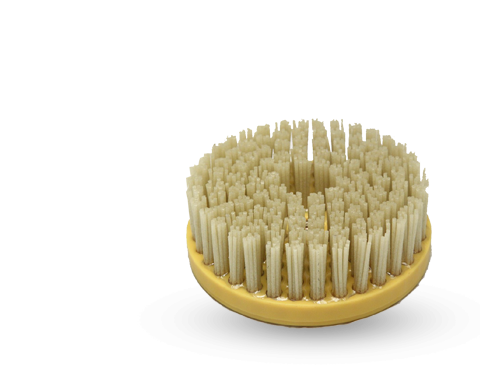

At SleekEven, we offer a variety of customization options for abrasive brushes, including shape, size, color, filament type, grit size, height of working part, etc.

125mm/150mm

Known for their exceptional hardness and durability, diamond filaments provide superior grinding and polishing capabilities. Ideal for hard materials, they ensure a smooth finish and longer lifespan, making them perfect for high-precision applications.

Natural color diamond brush filament

Natural color diamond brush filament

Red color diamond brush filament

Red color diamond brush filament

Silicon carbide filaments are highly effective for a variety of materials, offering a good balance of performance and cost. They are particularly well-suited for tasks requiring fine grinding and surface preparation, providing excellent cutting efficiency.

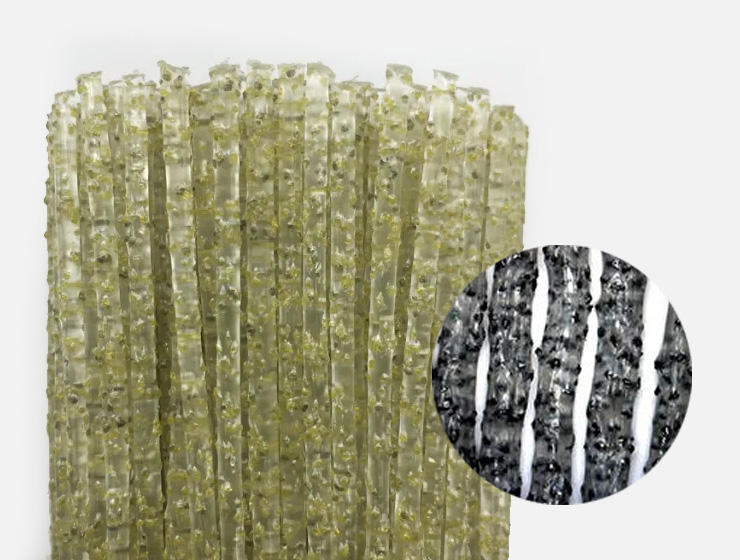

The DOSIC Dual Abrasive Filament combines the strengths of both diamond and green silicon carbide to deliver enhanced performance in abrasive applications. This innovative blend offers exceptional hardness and cutting efficiency, while also achieving a good balance between product performance and price, making it increasingly popular with customers.

These diamond abrasive filaments are game-changers for my stone grinding business! They cut down my processing time significantly and leave a flawless finish. Highly recommend!

I've tried various brushes both from European and China, but Sleekeven's abrasive brushes stand out. They work perfectly for my needs and are durable enough for heavy use. Will definitely order again!

SleekEven can customize stone cutting and grinding tools for granite, marble,sandstone, artificial quartz etc.

Contact us now to get a free sample.

Free SampleWe have stone tool experts who will provide you with the best grinding and cutting solutions quickly and for free.

Contact Now