Step 1

Requirement Analysis

We discuss your specific needs to determine the type, grit size, material, and performance characteristics required.

We discuss your specific needs to determine the type, grit size, material, and performance characteristics required.

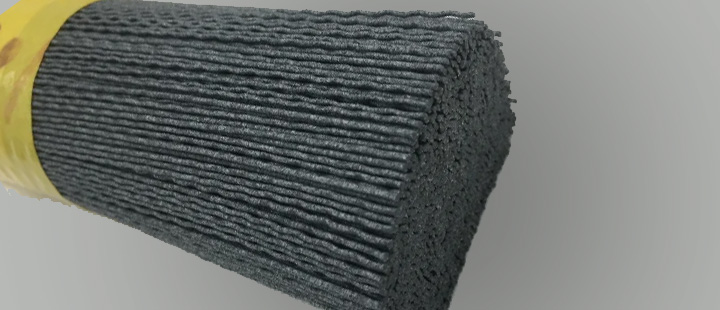

We choose the best materials, such as diamond, silicon carbide, or aluminum oxide, to ensure optimal filament performance.

Our team creates prototypes based on your specifications for initial testing and evaluation.

We conduct rigorous tests on the prototypes to ensure they meet quality and performance standards.

You evaluate the prototypes and provide feedback, which we use to make any necessary adjustments.

After approval, we proceed with mass production, maintaining strict quality control throughout the process.

We carefully package the filaments and arrange efficient shipping to ensure they reach you in perfect condition.

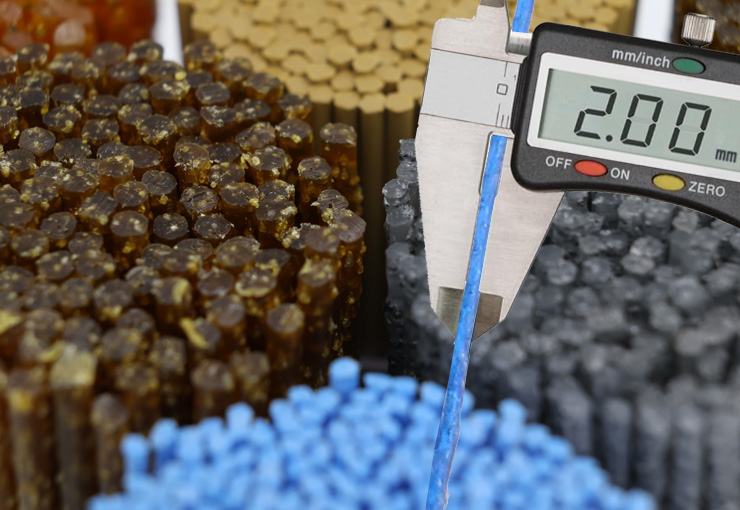

We offer a range of customization options, including:

Generally the loading percentage of diamond powder is between 5% and 25%.

Loading percentages of silicon carbide are normally from 25% to 30%.

In our stone processing operations, we faced challenges achieving a smooth finish on various surfaces, which often resulted in delays. After switching to Sleekeven's diamond abrasive filament, we improved our finishing quality and reduced processing time, leading to increased productivity and client satisfaction.

Our steel sheet finishing often encountered scratches and uneven surfaces, affecting product quality. After introducing Sleekeven's silicon carbide abrasive filament, the issues were resolved. It not only improved our sanding results but also reduced rework rates, greatly enhancing our production efficiency and customer satisfaction.

SleekEven can customize abrasive filament for granite, marble,sandstone, artificial quartz etc.

Contact us now to get a free sample.

Free SampleWe have abrasive filament experts who will provide you with the best solutions quickly and for free.

Contact Now